Klay Blog

Making our Round Throws

Kirsty first made a series of these throws around fifteen years ago, and we have wanted to make them again ever since. Making them is slow and they require long stretches of attention, which has meant waiting for the right moment to begin again. This recent series was completed gradually over a few months, made by four of us, working in stages as time allowed.

This blog post shares how the throws are made, from the materials and construction to the references that inspired them. It is a record of the many small, careful steps involved, and why these pieces can only ever be produced in very limited numbers.

This was one of the very first samples that Kirsty made around 20 years ago. She hand dyed leftover linens and cottons from film jobs she had worked on, then cut them into strips. She never ended up backing this one. We like seeing the raw backside. She still uses it a lot. Its lightness and floppiness inspired us to not use batting in our new series.

Reference

Some of the inspiration for the throws

There was actually a lot of things we referred to for these. Here are some of the key things that inspired them.

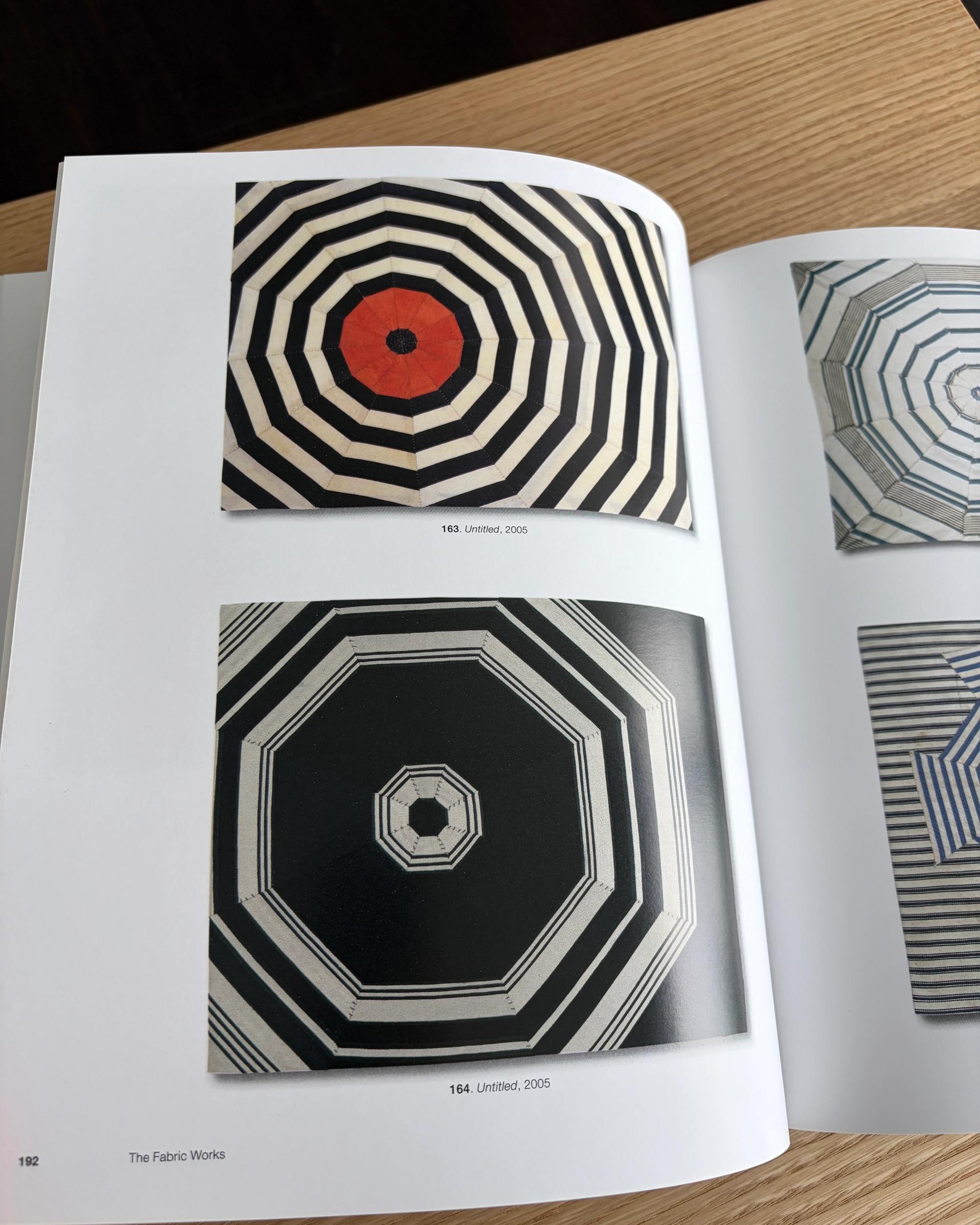

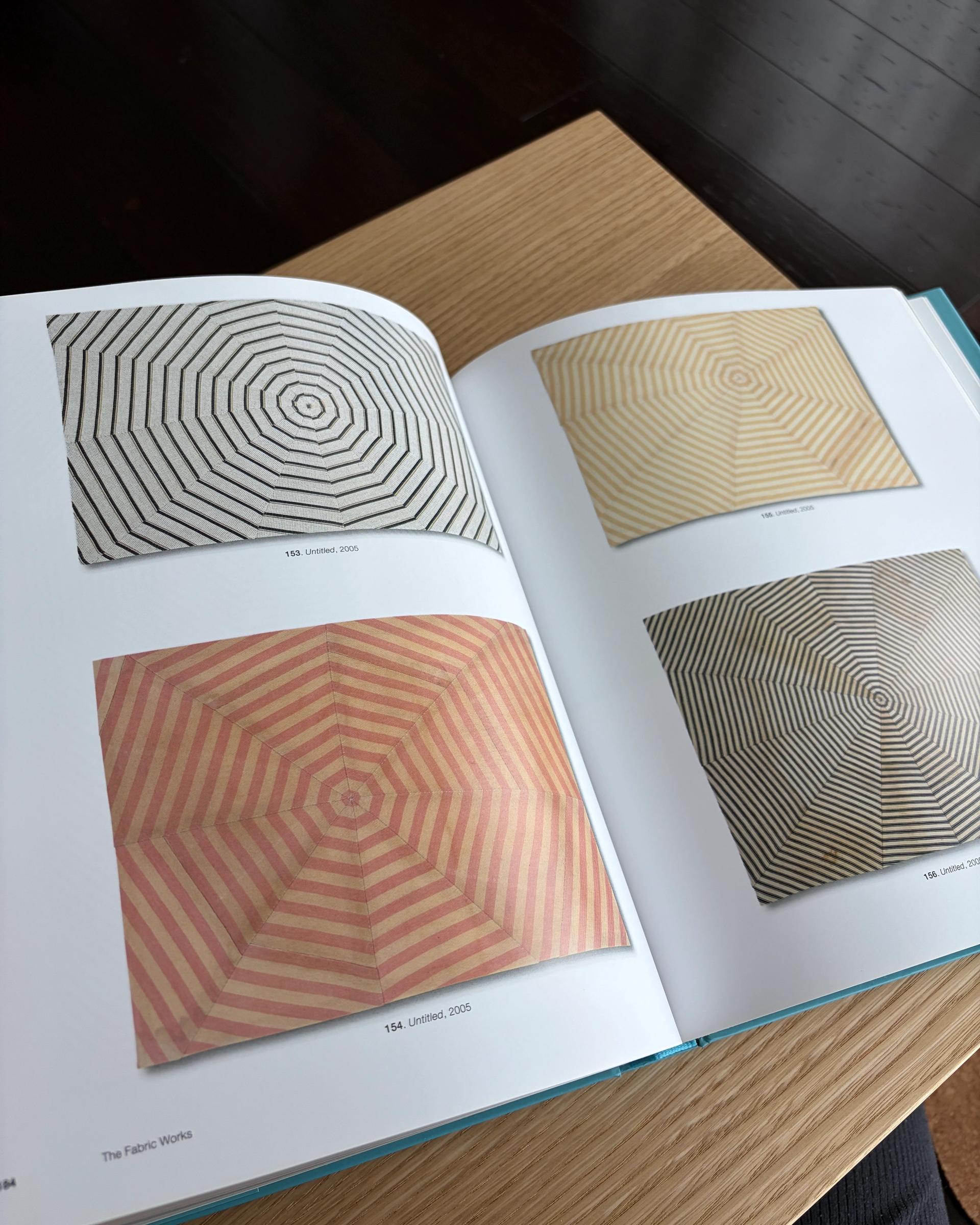

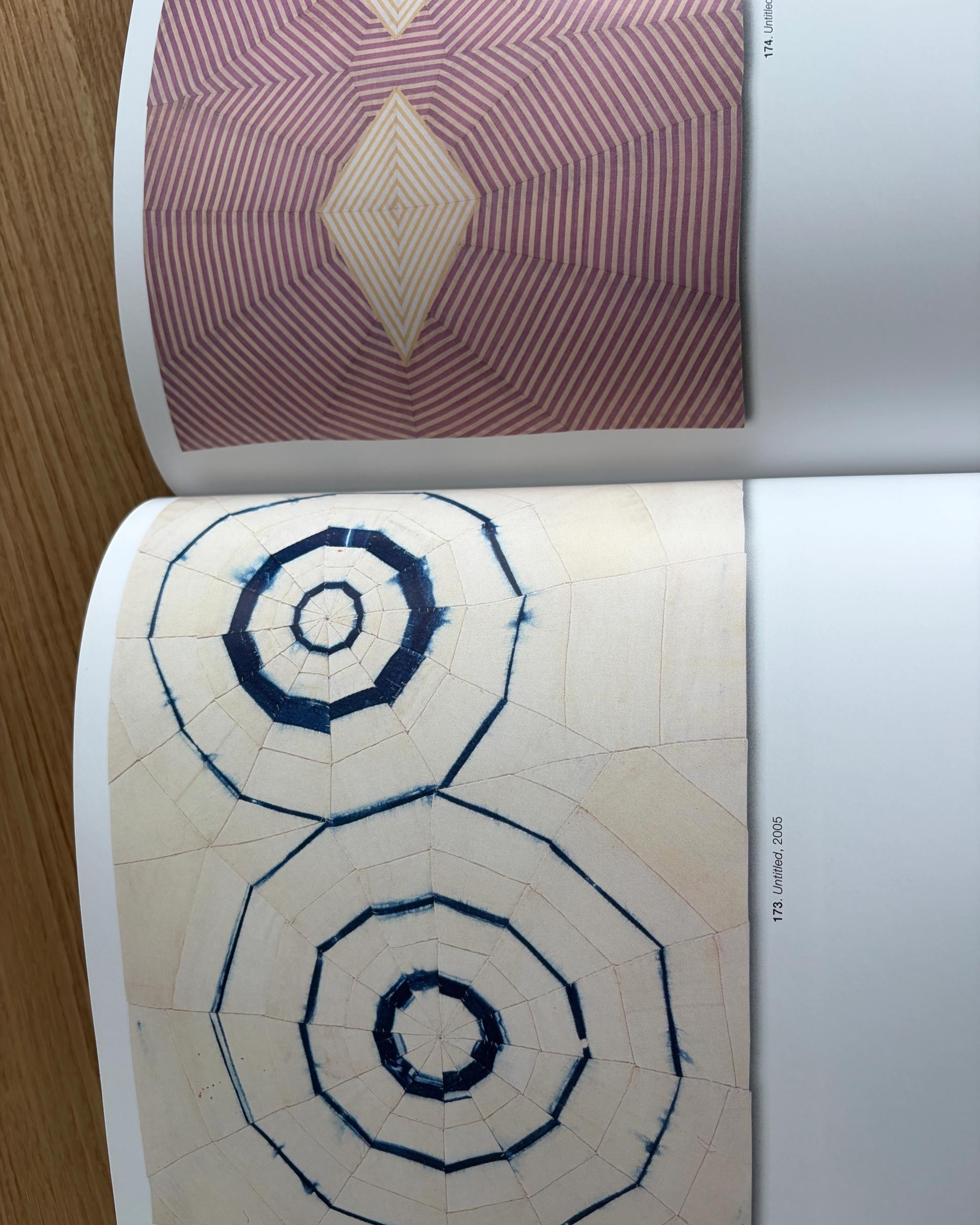

Kirsty was very inspired by Louise Bourgeois textile works after seeing an exhibition in London when she lived there.

Images from the book 'Louise Bourgeois The Fabric Works', published by Skira

She was also inspired by vintage images of handmade paper umbrellas

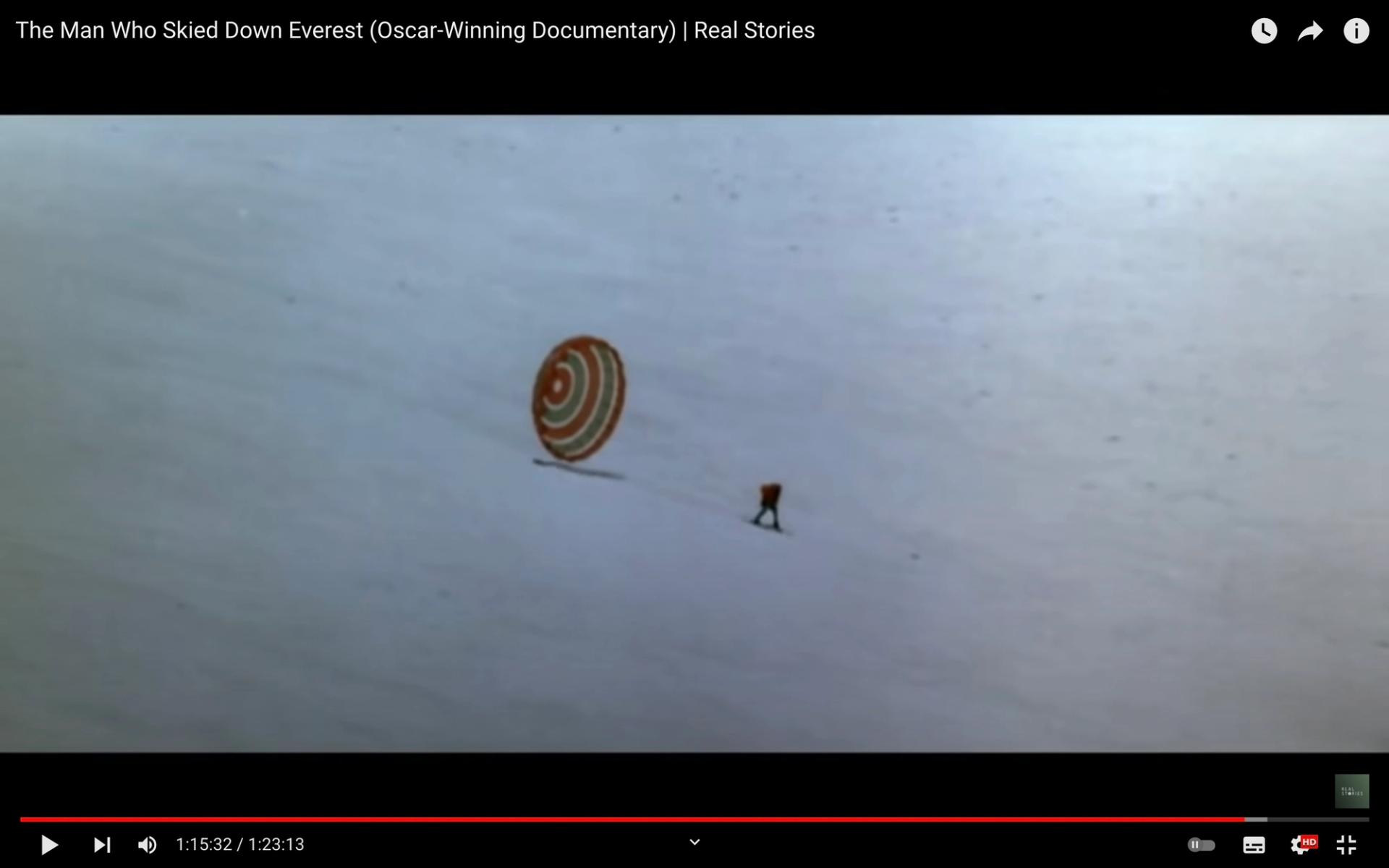

We were also very inspired by old parachutes and in particular the one in the beautiful film 'The Man who Skied Down Everest'. You can watch the full movie on youtube here.

The last limited series

We made the last batch of these about 15 years ago

Here are some of the last series that Kirsty and I made together about 15 years ago. In this photo they are partway through making. They have not had their backs attached yet.

More photos above of some of the last throws we made about 15 years ago. These were smaller than the ones we have just made. We sold the last throws through our friend Leilani's online store called Bon Weekend (since closed). These photos are from Bon Weekend days.

This latest series

Our latest range is bigger than our last one. We explored a lot of different patterns and decided on the ones above after weeks of tweaking, discussions and referring back to references and playing with colour samples.

We always knew we wanted to repeat that first original one that Kirsty made all of those years ago with the blue and white stripe.

The stripes are made from cut strips of 100% hemp that are sewn together.

These are then cut into the triangular shapes to create the circle forms.

We fuse the backside in certain places for extra strength in the centres.

Sewing the panels together. Kirsty changes thread colour as she goes through different colour blocks.

Each strip is sewn together on the straight sewer and then again with the overlocker. We do this so that it will not fray inside and to create a tactile surface that emphasises the join marks. The overlocking makes a gentle bump at each join.

There is a lot of pressing that happens throughout. Each seam is pressed down to set it in place before the next process is started.

It is so satisfying when all of the panels come together. We love seeing and feeling the ridges of the joins.

Kirsty's so skilled at making these. I love looking at the joins and how they come together.

We are lucky to have a generously sized workroom where we can place components of the different throws at various stages as it can get confusing with all the hundreds of parts to each one and processes involved.

Once the fronts are joined together and pressed into place, we cut out the calico backing to get ready to attach the fronts.

Then we pin the fronts to the calico using special quilting pins.

Two of us do this process together to make sure it is neatly attached. We use a ruler a lot to flatten it into shape.

Once pinned, it is secure to remove from the large cutting table and start the process of joining the front to the back.

Kirsty does a temporary basting stitch in the centres to keep it in place while it is being joined on the machine and when hand tufting. These are removed when the throws are finished.

The edges of the throws are finished with binding that matches the last colour strips.

Then these get an extra layer of joining by Kirsty hand sewing them together in places.

From the back/ underside they look like parachutes to me! This one is waiting to be hand sewn together.

This offcut was used by Kirsty to test and refine the hand stitching used to finish the throws. These stitches all look very similar but are slightly different.

Each throw comes pre-washed, pressed and rolled up inside a calico bag.

Using the throws

at home

These throws are designed to live on your bed, couch or armchair. Unlined and lightweight, they are soft and flexible in the way they move, offering a gentle comforting additional layer when resting at home.

Kirsty at home on the couch with one of her new throws. She kept one of this style. It is lightweight, floppy and comfy as a extra gentle layer.

At 2.2m in diameter, the scale of these throws allows them to sit across a whole sofa, reading as a textile piece that becomes a feature in the room when not being used as a blanket.

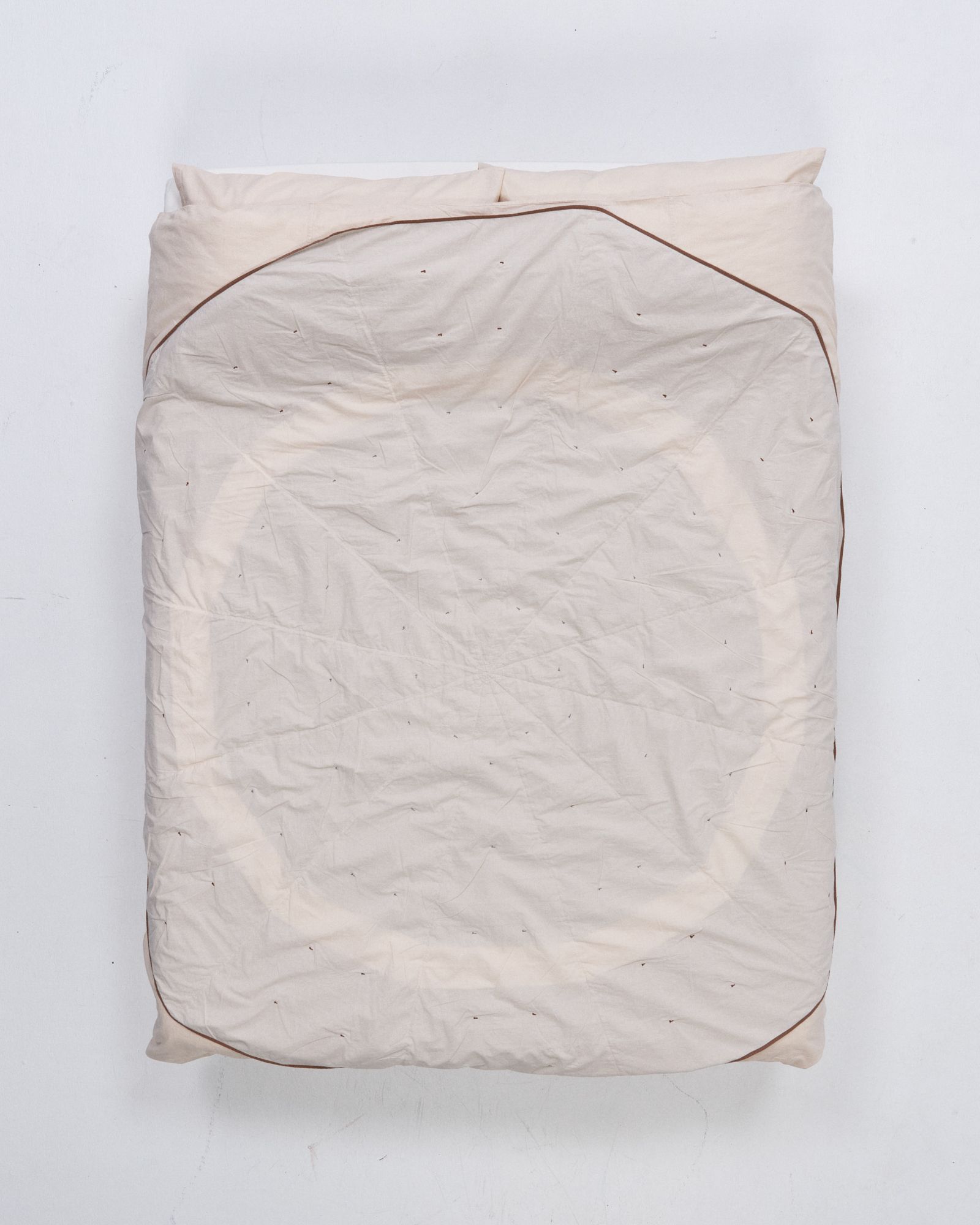

The same applies in a bedroom. Their scale works well across a bed, particularly when paired with simple bedding such as our calico duvet covers.

They do also look lovely paired with patterned and coloured bed linens, like these pillowcases here.

The hand sewn details are very lovely. The threads we used are colour matched to the colour of whatever stripe they are connected on.

The images above show the fluid quality of the unlined throws. They drape and gather easily, with a softness and character that comes from the way they are constructed.

The backside/ reverse of the throws reminds us of the construction of vintage silk parachutes, with a diagonal sewing pattern that becomes more apparent from the back. We chose not to line the throws in order to preserve their soft, fluid drape, and also because we were drawn to how the surface changes in different light. When held up, the pattern from the other side becomes visible, and the reinforced seam joins can be felt through the cloth. From the back, the hand-sewn joins and the binding around the edge are clearly visible, emphasising the construction of the piece.

Image of a vintage parachute from Etsy.

We called this one Ripple because it reminded us of the patterns formed when a stone is thrown into water. The ripple texture is particularly tactile and becomes more pronounced when the throw is casually draped or has been used.

This is the most minimal of the series, made entirely from soft pink strips. The pattern and texture are more subtle than the others, allowing the tactile, handmade quality of the joins to take centre stage.

This might be the boldest one.

There are 11 designs to choose from. All are the same size, with the same strip widths and finished using the same careful processes. The throws vary only in colour and pattern. This is a very limited edition, and while we hope to make more in the future, we cannot say when.

Looking after your throws at home

Gentle, easy care for a handmade heirloom.

These throws should be hand washed at home, in a bath or a very large bucket. We do not recommend dry cleaning. Care instructions are provided on the labels sewn into each throw; please follow them. Further tips can be found on our care page here.